Terminal Operating System (TOS)

The Terminal Operating System makes full use of technological means such as the mobile internet, the Internet of Things (IoT), sensor networks, big data, the remote operation of large-scale equipment and graphical management. Through sophisticated algorithms, it manages production tasks, resources and information, enabling normalized processes, paperless operations and collaborative business management innovation.

Main Application Scenarios:

Container TOS

The Container Terminal Operating System supports automated task allocation for yard cranes and tractors, optimizes container stacking planning, and enhances yard storage management to minimize shuffling. It supports intelligent tallying and automated gate operations at the quayside. This system provides a comprehensive IT solution for container terminal operations to achieve efficient, precise, and intelligent container port management.

Bulk & Cargo TOS

The Bulk & Cargo Terminal Operating System supports unmanned gate operations and integrates control of quayside cranes, belt conveyors, bucket wheel stacker reclaimers and ship unloaders. Offering multi-access via online platforms, mobile apps and a WeChat mini-program, it enables real-time operational monitoring and intelligent management through multi-terminal collaboration, ensuring flexible and highly coordinated terminal operations.

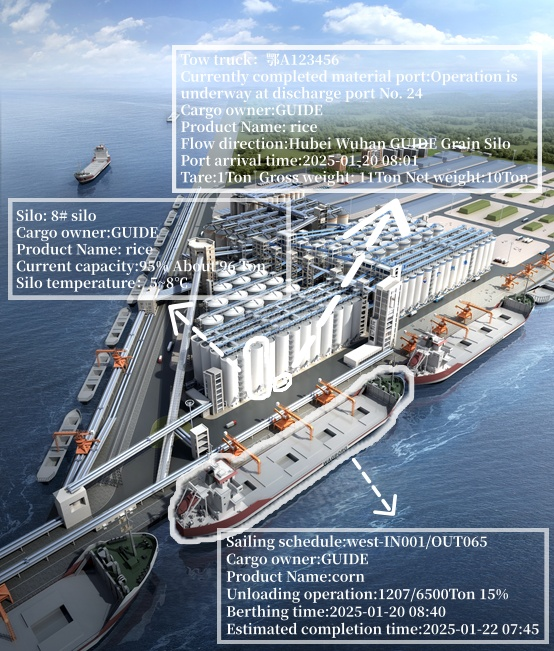

Grain & Oil TOS

The Grain & Oil Terminal Operating System achieves seamless coordination across ship loading/unloading, port dredging operation, oil tube operation, and silo management. Leveraging integrated functions such as WeChat appointment, navigation, sign in, automated queuing, yard entry guidance, route optimization, position guidance, and automatic loading, it synchronizes with smart gates and unmanned weight rooms. Real-time data integration enables status monitoring, belt conveyor control, and route calculation, achieving full-process automation for grain and oil terminal operations. This system delivers an comprehensive digital solution for grain and oil terminal operations, helping customers realize efficient, precise, and intelligent production management.

Core Functional Descriptions

Intelligent Tallying

Upgrading the workflow of the original tallying processes, improves working conditions for tallying personnel.

Cost Reduction & Efficiency Gains

Automated residue inspection

Intelligent signature verification

Refines production workflows to realize higher-quality services

Intelligent Scheduling

It enables dynamic optimisation and collaborative management of intelligent scheduling across the entire port production process. It supports real-time analysis, intelligent, algorithm-based decision-making and automated operations, significantly enhancing port operational efficiency.

Intelligent Gate Control

It integrates with weighbridges, CCTV cameras and other devices. It features licence plate recognition (LPR) and container number recognition. It achieves fully automated gate inspection and access control, boosting throughput efficiency.

Previous:Smart Port Platform (SPP)