Enterprise Asset Management (EAM)

By leveraging information technology and advanced techniques, this platform integrates multi-sensor fusion and forms a unified system encompassing "data acquisition – business processing – intelligent analysis – decision support – management optimization". It ensures continuous, stable, and efficient equipment operation, optimizes resource allocation (personnel, finance, materials), and improves energy consumption efficiency (water, electricity, oil, natural gas).

Core Functional Descriptions

Intelligent Predictive Maintenance

It is based on equipment operational data and AI algorithms, and involves predicting potential failures and automatically generating preventive maintenance work orders. Digital management of equipment history records enables full life cycle tracking, from procurement and inspection to repair and decommissioning.

Digital Procurement Management

Smart Pricing Engine: Integrates an intelligent price comparison system with supplier KPI evaluation, supporting one-click generation of multi-dimensional procurement analysis reports.

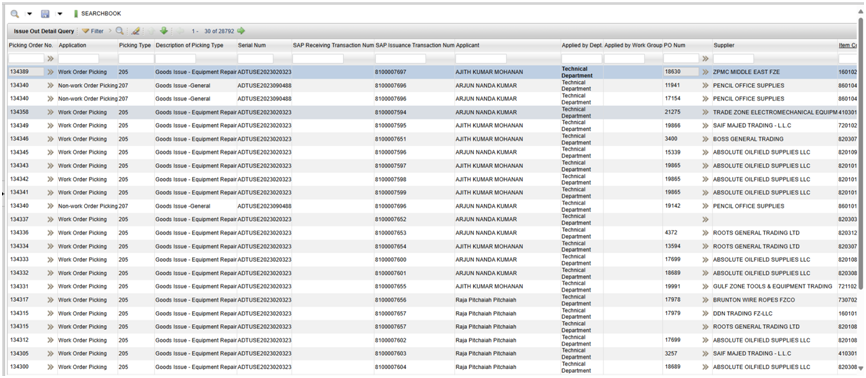

Transparent Supply Chain: Electronically links contracts, orders, and acceptance documents, achieving full-lifecycle visibility from requisition to inventory.

Data Integration

Seamlessly connects with ERP, financial, and production systems, automatically updating asset ledgers, storage status, and budget data.

Accroding to the unified board demonstrates the key metrics such as equipment OEE (Overall Equipment Effectiveness) and material turnover rates.

Decision Support & Reporting

Through big data analysis, it generates equipment replacement advice, spare parts safety stock models and procurement cost fluctuation alerts. It also supports real-time approval workflows and report generation on mobile devices, providing executives with data to support their decision-making, such as equipment utilization heat maps and material consumption trends.